Most of the currently available solar panel choices fall into one of three types: monocrystalline, polycrystalline (also known as multicrystalline), and thin-film. These solar panels differ widely in how they are manufactured, size, efficiency, costs, and the facilities for which each is ideally suited.

Depending on the type of installation that you are considering, one choice may be more fitting than the others.

Major Solar Panel Forms

Three main types of solar panels exist: monocrystalline, polycrystalline, and thin-film. That design has its own unique advantages and disadvantages, and the type of solar panel that is ideally suited for your installation will rely on property-specific factors and the desired system features.

Below we will break down some common solar panel questions and concerns and how different types of panels have varying characteristics.

Solar cells are constructed from a semiconductor material that transforms light into electricity to generate electricity. Silicium is the most common material used as a semiconductor during the process of producing solar cells.

Solar panels are monocrystalline and polycristalline

Solar mono- and poly-panels

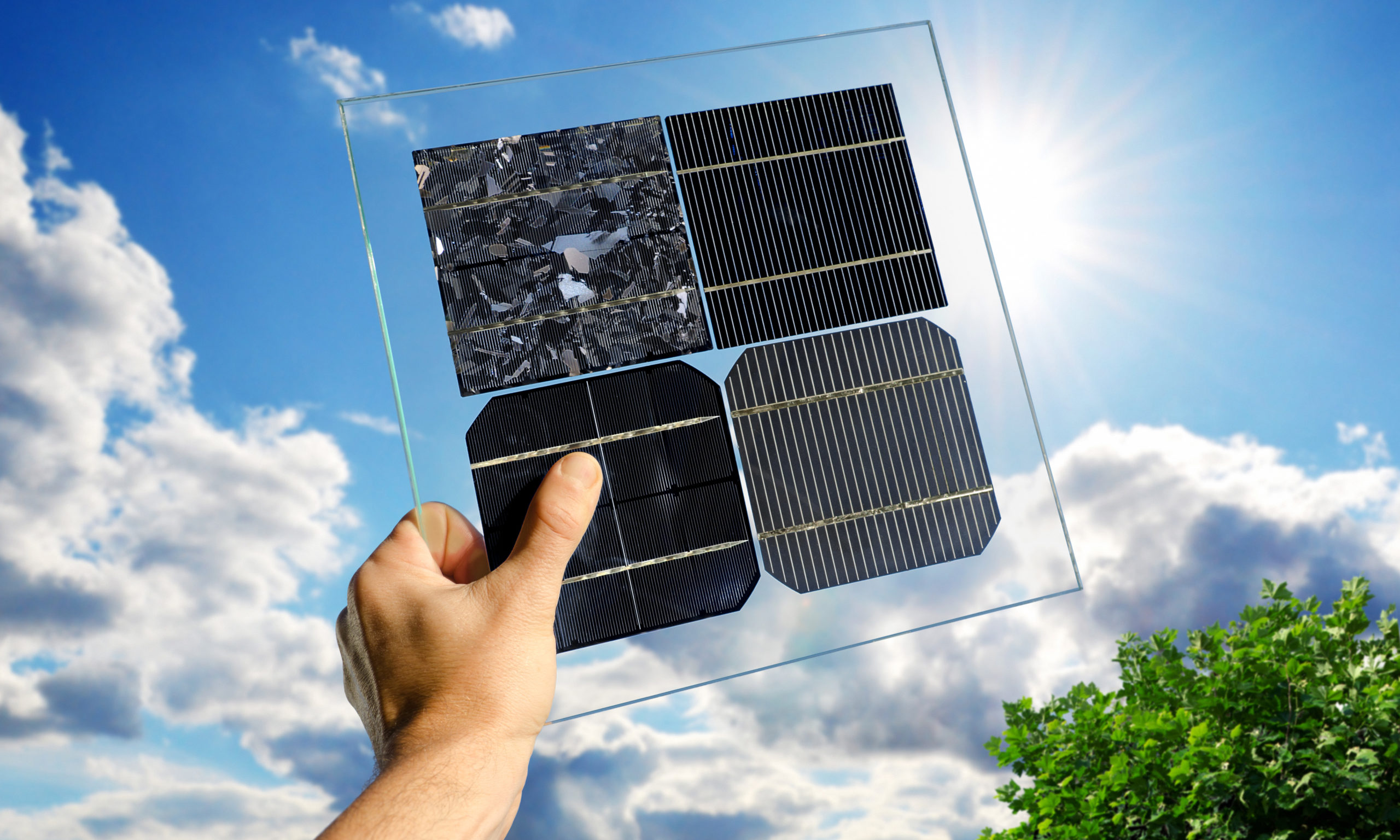

All monocrystalline and polycristalline solar panels have silicon wafers made of cells. Wafers are arranged into rows and columns to form a circle, covered with a glass sheet, and placed together to create a monocrystalline or polycristalline stand.

Although all of these solar panel styles have silicon-made cells, monocrystalline and polycrystalline panels differ in the silicon composition itself. Monocrystalline solar cells are made out from a single, pure silicone crystal. Additionally, polycrystalline solar cells are made of silicon crystal fragments, which are melted together in a mould before being cut into wafers.

Solar panels made from thin film

Small Solar Screen Panels

Thin-film panels are constructed from a variety of materials, unlike monocrystalline and polycrystalline solar panels. The most prevalent form of thin-film solar panel is made of telluride cadmium (CdTe). Manufacturers put a layer of CdTe between transparent conducting layers to make this type of thin-film panel that help catch sunlight. This form of thin-film technology often has a protective glass coating at the rim.

Thin-film solar panels can also be made of amorphous silicon (a-Si), which is close to the monocrystalline and polycrystalline panel structure. Although they use silicon in their construction, these thin-film panels are not made of solid silicon wafers. Alternatively, they are made of non-cristalline silicon mounted on top of glass , plastic or metal.

Finally, Panels from Copper Indium Gallium Selenide (CIGS) are another common form of thin-film technology. All four elements of the CIGS panels are placed between two conductive layers ( i.e. glass, plastic, aluminium or steel) and electrodes are placed on the front and back of the material to capture electrical currents.

The material and manufacturing variations cause differences in appearance between each type of solar panel:

Solar Monocrystalline Panels

Photovoltaic solar cells

If you see a black cell solar panel it is a monocrystalline panel most likely. Owing to how light interacts with the pure silicon crystal these cells appear black.

Although the solar cells themselves are black, the back sheets and frames of monocrystalline solar panels have a range of colours. The solar panel's back layer will most frequently be black, silver, or white, while the metal frames are usually black or silver.

Photovoltaic solar cells

Like monocrystalline solar cells, polycrystalline solar cells appear to have a bluish hue because of the light that reflects silicon fragments in the cell in a different way than a pure monocrystalline silicone wafer reflects.

Polycrystalline panels have different colours for back sheets and frames, similarly to monocrystalline ones. The frames of polycrystalline panels are most often red, and the back sheets are either white or grey.

Solar cells with thin films

When it comes to thin-film solar panels the biggest differentiating aesthetic factor is how thin and low-profile the technology is. The thin-film panels are always slimmer than other panel ty[es, as their name indicates. It is because the cells within the panels are nearly 350 times thinner than those used in monocrystalline and polycrystalline solar panels.

It is important to note that while the thin-film cells themselves can be much thinner than conventional solar cells, a whole thin-film panel may be comparable in thickness to a monocrystalline or polycrystalline solar panel if it has a thick frame in it. There are adhesive thin-film solar panels lying as-close-as-possible on a roof sheet, but there are more durable thin-film panels with frames up to 50 mm thick.

Based on what they are made from, thin-film solar panels will come in both blue and black hues as far as colour goes.

Bifacial solar panels can absorb sunlight from both the front and back of the panel and thus generate more energy than typical solar panels of comparable size. Many bifacial solar panels would have a transparent back sheet so that sunlight can pass through the plate, bounce off the ground surface and back upwards towards the back side of the panel's solar cells. Usually these solar panels are made with monocrystalline solar cells but there are also polycrystalline bifacial solar panels.

Each type of solar panel varies by how much power it can produce.

Solar panels are monocrystalline and polycrystalline

Monocrystalline has the highest efficiencies and power efficiency usually of all types of panels. Monocrystalline solar panels can achieve efficiencies higher than 20%, while polycrystalline solar panels usually have efficiencies ranging from 15 to 17%.

Monocrystalline solar panels have a tendency to generate more power than other types of panels not only because of their efficiency but also because they have come in higher wattage modules. Some monocrystalline solar panels come with power capacity approaching 300 watts (W), some even approaching 400 W at present. In comparison, polycristalline solar panels tend to have lower watts.

This does not mean that monocrystalline and polycrystalline solar panels are not practically the same size-in fact, with 72 or 96 cell variants (usually for large-scale installations), both types of solar panels appear to come with 60 silicon cells each. Yet monocrystalline panels are capable of generating more energy even with the same number of cells.

More production

Solar panels made from thin film

Thin-film solar panels tend to have fewer strength and efficiencies than monocrystalline or polycrystalline types. Based on the particular material used in the cells, efficiencies can vary, but they typically have efficiencies closer to 11 per cent.

Unlike monocrystalline and polycrystalline solar panels which come in standardised variants of 60, 72 and 96 cells, thin-film technology is not available in uniform sizes. As such, the power capacity from one thin-film panel to another would depend largely on its physical dimensions. The power capacity per square foot of a monocrystalline or polycrystalline solar panel would typically surpass the thin-film panel technology.

Will solar panels have over 96 cells in them?

Although not as common as 60, 72, or 96 cell panels, some manufacturers of solar panels produce solar panels with half-cut cells that essentially double the number of solar cells inside the panel. Half-cut solar cells are monocrystalline solar cells that are sliced in half using a laser cutter. Solar panels will experience small gains in effectiveness and longevity by cutting the solar cells in half.

Various types of solar panels have variable costs

Manufacturing methods vary between monocrystalline, polycrystalline, and thin-film; as such, there is a specific price tag for each form of plate.

Most costly

Solar Monocrystalline Panels

Of all types of solar panels, the most costly choice is probably monocrystalline panels. It is primarily due to the manufacturing process-since the solar cells are made from a single silicon crystal, the manufacturers have to bear the costs of such crystals produced. This process , known as the Czochralski process, is energy-intensive and leads to waste silicone (which can be used later to create polycrystalline solar cells).

Low Price

Photovoltaic Solar Panels

Technically, polycrystalline solar panels are cheaper than monocrystalline solar panels. It is because the cells are made from fragments of silicone rather than a single, pure crystal of silicon. This makes a much easier method of producing cells, thereby costing less for producers and ultimately end users.

Top loss

Solar panels made from thin film

Whether you pay for thin-film solar panels would rely primarily on the type of thin-film panel; CdTe is usually the cheapest type of solar panel to manufacture, while CIGS solar panels are far more costly to produce than either CdTe or amorphous silicone.

Whatever the cost of the panel itself, the total cost of installing a thin-film solar panel may be lower than installing a monocrystalline or polycrystalline solar panel system because of additional labour requirements. Installations of thin-film solar panels are less labor-intensive because they are smaller and more manoeuvrable, making it simpler for installers to bring panels onto the rooftops and to secure them in place. It means lower labour costs which can lead to a less costly solar system in general.

Type of panel best suited for installation

When you select the type of solar panel you would like for your device, much of your decision will come down to the property and situation details. Monocrystalline, polycrystalline, and thin-film panels each have their own advantages and disadvantages, and depending on your property and ambitions for the solar project, the solution you will move forward with.

Property owners with plenty of room for solar panels can save money up front by installing polycrystalline panels with lower performance, less expense. If you have limited space, and you are looking to optimise your choice